Keil System

In the keil system, the panels must first be drilled and drilled using a special undercut drill to place the anchor in a standard way, then the undercut anchor and a special clamp are placed on the hole created in the panel and fastened with a washer screw. They fix each other.

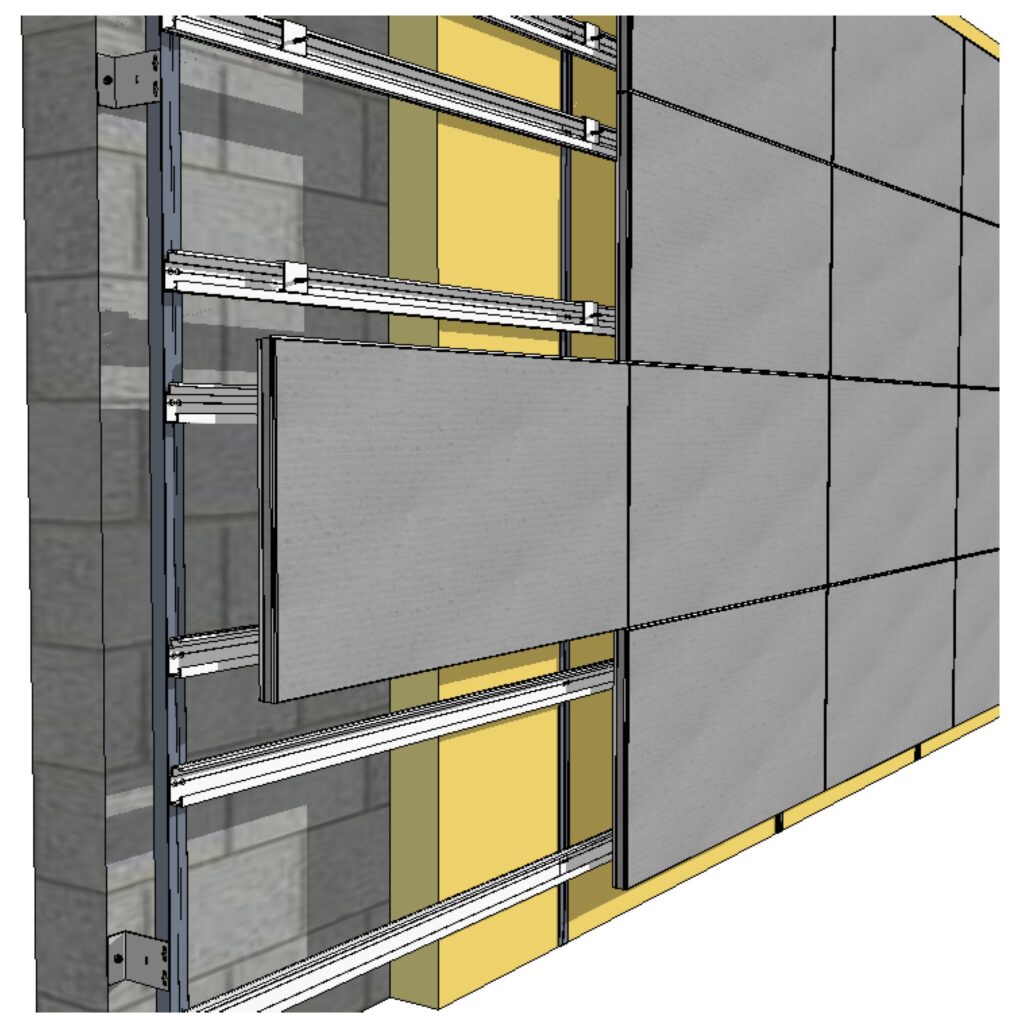

After the preparation stage, the panel is installed and adjusted on the aluminum foundation that is placed horizontally on the main structure.

The keil system can be called the most modern and attractive method of panel installation in the outer shell of the building, which has been able to quickly open its place among the designers of advanced societies by hiding the installation connections behind the panels.

Keil System Products

To view the products, click on the relevant category.

Features

High resistance in harsh weather conditions

Long life, low maintenance cost (affordable)

A beautiful view free from visual pollution caused by additional connections on the facade cover

High safety against earthquakes and pressures

Ability to run in large sizes

Creative and unlimited design for modern facades

Quick and easy installation compared to traditional facades (mortar).

The possibility of combining materials in different shapes and sizes

Implementation of the dry facade system using the keil method

The keil system is one of the most widely used systems in this industry.

In this system, drilling tools, aluminum fittings, steel fittings and cladding reinforcement materials are used.

In the following, we will discuss how to implement each of these parts.

1. Drilling tools

The motor of the undercut drill machine is German Bosch. Here, the device is connected to the table with air and water pump. The undercut drill is used to make holes on the façade (stone, ceramic, etc.). The drill used in this drill is made of diamond.

2. Aluminum fittings

Aluminum runners in this system are connected horizontally to the vertical iron cans of the substructure. The hooks used in this system are also made of aluminum. Aluminum hooks are attached to the facade cover, and finally, hooks are used to fix the aluminum runners.

3. Steel fittings

In this part, according to the cladding material, the right size anchor is used to insert into the hole created by the drill machine in the tile.

According to the size of the anchor, the appropriate screw is used to connect the hook to the facade cover.

There are three types of connection methods to connect the anchor to the hook.

The first method: connecting the anchor with a spanner screw, in this method, according to the size of the anchor, a screw with a suitable height and a washer are used.

Second method: In this method, the anchor is connected to the solar screw, the solar screw has a washer, so there is no need for a washer in this method.

The third method: The anchor is connected to the Allen screw. In this method, there is no need for a washer because the bolt is attached to the head of the anchor.

4. Facade reinforcement materials

One component glue and lace are used to reinforce and secure the facade cover.

One component glue does not need any other ingredients to combine.

The net can be ordered and implemented in springs of 3×3 and 4×4.